Dedicated Customer Teams & Agile Services

Roto Moulding at Its Best — by Thermopack

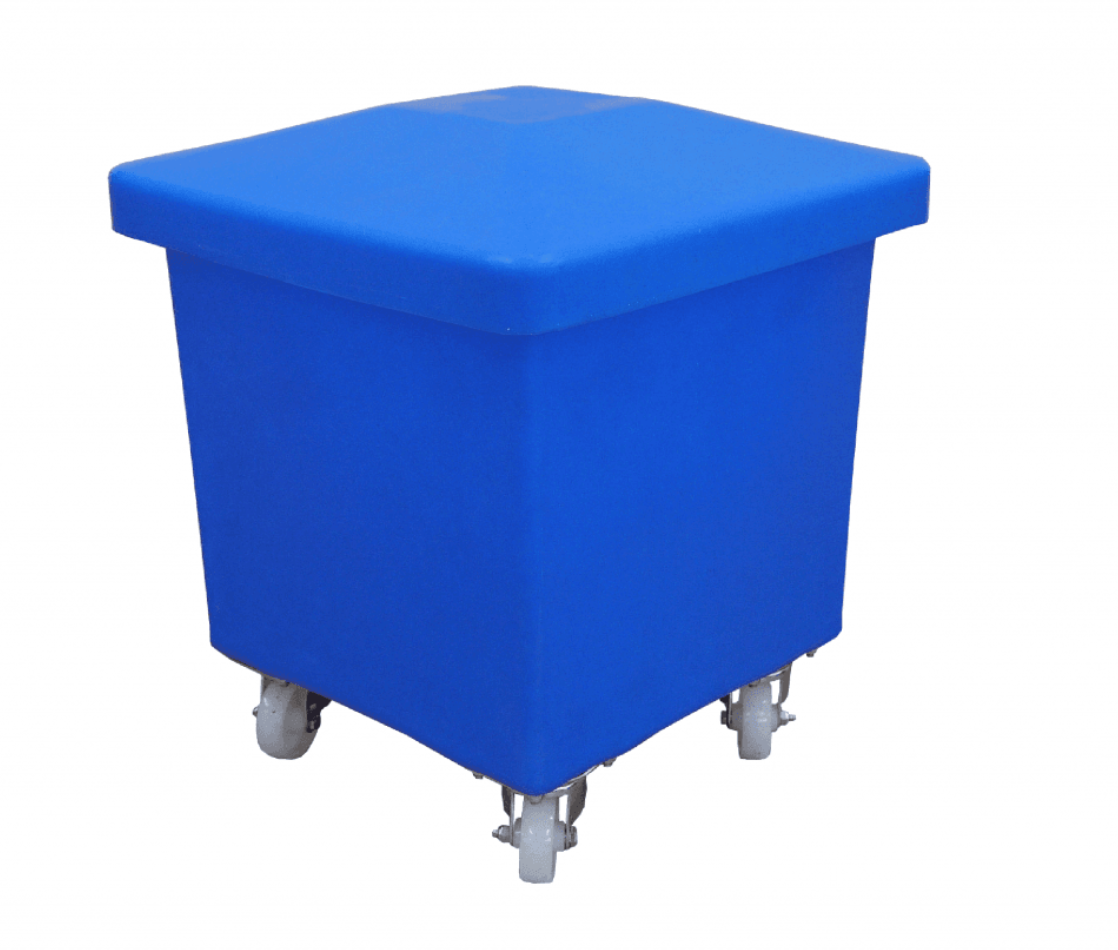

At Thermopack, we set the benchmark for precision roto moulding across industrial tanks, hoppers, fuel tanks, and high-performance automotive parts. Our process delivers stress-free, single-piece mouldings with uniform wall thickness, exceptional impact resistance, and proven durability in harsh environments. Using premium UV-stabilized polyethylene grades (LLDPE/HDPE) and application-specific compounds , we engineer solutions that stay dimensionally stable, corrosion-proof, and maintenance-light across years of service.

From CAD to component, our DFM-led team optimizes geometry for even material flow, ribbing, bosses, and inserts—enabling complex shapes, undercuts, double-wall sections, and foam-filled options without weld lines. For tanks and hoppers, this means seamless vessels with superior leak integrity, integrated baffles, sight-glass ports, manways, and molded-in fittings sized to your process. For fuel tanks and automotive parts, we pair robust tooling with precise cooling control and CNC finishing for repeatable fitments, reduced NVH, and assembly-ready accuracy.

Quality is built into every step: material traceability, SPC on critical dimensions, hydrostatic and leak testing for tanks, drop/impact validation, and ultrasonic thickness mapping—under an ISO 9001:2015 quality system. With agile in-house tooling, quick design iterations, and scalable production, Thermopack shortens your time-to-market while lowering total cost of ownership.